Common Problems and Solutions for PP Woven Bag Printing

Printing on polypropylene (PP) woven bags is essential for enhancing product appeal, providing important descriptions, and boosting sales. This process involves various printing methods such as letterpress, flat printing, gravure printing, screen printing, and orifice printing. However, challenges often arise during the printing process. This article details common problems encountered in PP woven bag printing and their respective solutions.

1. Ink Adhesion Issues on the Substrate

Ink adhesion problems are among the most prevalent challenges in PP woven bag printing. Understanding the ink adhesion mechanism is crucial for resolving these issues.

1.1 Ink Adhesion Mechanism

- Wetting: Strong adhesion relies on the molecular interaction between the substrate film and the ink binder.

- Compatibility: The ink and substrate should have similar polarity to ensure optimal compatibility.

1.2 Causes and Countermeasures for Weak Adhesion

- Insufficient Surface Corona Treatment:

Substrates must have adequate surface tension for proper ink adhesion. The recommended surface tension is ≥38 mN/m for PP and PE, ≥50 mN/m for PET, and ≥52 mN/m for NY. Use a dyne pen to measure surface tension before printing. - Poor Storage Conditions:

Additives like lubricants can migrate to the surface over time, forming a weak interface. Store substrates under controlled conditions and test surface tension before use. - Moisture Absorption:

Materials like PA, PVA, and PT are prone to moisture absorption, reducing adhesion. Preheat substrates and store them in a temperature- and humidity-controlled environment. - Incorrect Ink Type:

Different substrates require specific types of gravure inks. Always check operating instructions to select the correct ink type. - Ink Whitening and Deterioration:

Deteriorated or improperly dried ink can drastically reduce adhesion. Ensure proper drying temperatures are maintained.

2. Overprint Errors

Overprint errors occur when multiple colors fail to align perfectly, leading to mismatches in the final design.

2.1 Personnel Quality

Printing requires meticulous attention to detail. Employees should:

- Be well-trained and attentive.

- Conduct regular self-inspections during the printing process.

- Quickly identify and address any color registration issues.

2.2 Equipment Factors

- Equipment Accuracy:

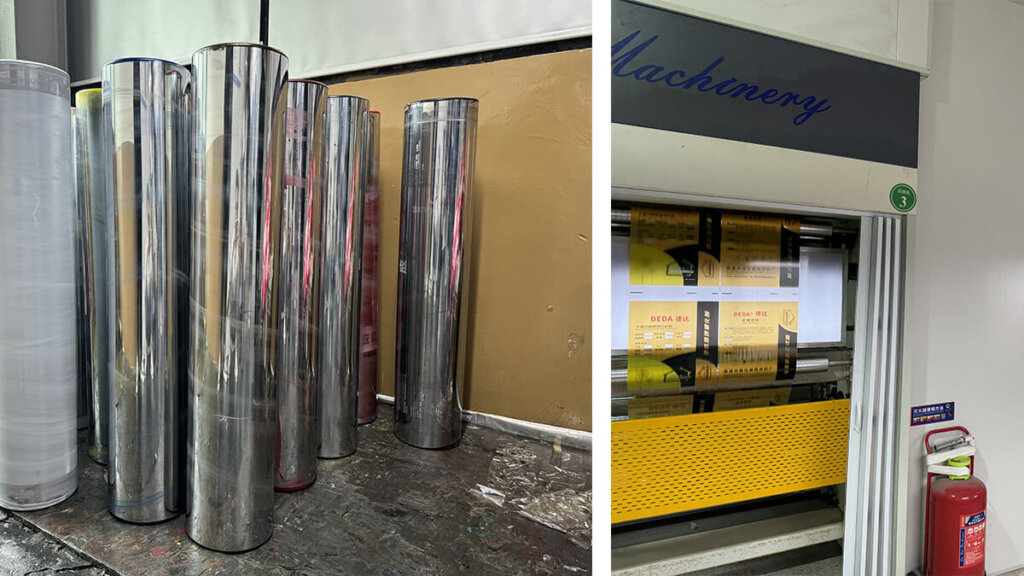

Ensure proper maintenance of tension control, heating systems, air supply, and embossing rollers. Regularly check halogen bulbs or photoelectric devices used for color registration. - Plate Roller Issues:

Improperly adjusted plate rollers can cause inaccuracies in color registration. Regularly inspect plate rollers for proper alignment.

2.3 Operation Process

- Tension Settings:

Incorrect tension settings can lead to misalignment. Adjust tension according to substrate requirements. - Temperature Control:

High oven or cooling roller temperatures can deform the substrate. Optimize preheating and cooling temperatures based on film properties. - Air Intake and Exhaust Balancing:

Imbalanced airflows can cause substrate shaking, leading to misalignment. Measure air intake and exhaust with an anemometer.

3. Scraper Line Marks

Scraper line marks are frequent defects that compromise print quality, appearing as streaks or lines during the printing process.

3.1 Causes of Scraper Line Marks

- Line Marks Without Ink:

Caused by hard inorganic impurities such as sand in the ink that embed into the scraper blade. - Continuous Line Marks with Ink:

Result from soft particles lifting the scraper blade or damaged scraper blades. - Fine Filament Scraper Marks:

Often caused by impurities or inadequate plate roller surface finish.

3.2 Treatment Countermeasures

- Scraper Blade Maintenance:

Inspect and grind scraper blades before installation; avoid mixing oil used for grinding with ink. - Dust Management:

Maintain a clean printing environment by installing air filters and regularly testing dust content. - Plate Roller Adjustments:

Use metallographic sandpaper to grind rough plate rollers; return severely damaged plates for reprocessing if necessary. - Ink Adjustments:

Reduce ink viscosity to prevent excessive friction; filter ink to remove impurities. - Environmental Control:

Maintain optimal temperature and humidity levels in the printing workshop to reduce static and friction issues.

Conclusion

By addressing common problems such as ink adhesion issues, overprint errors, and scraper line marks, PP woven bag printing processes can achieve higher efficiency and better quality outcomes. Regular equipment maintenance, proper substrate handling, and optimized environmental conditions are critical in minimizing defects. Implementing these solutions will ensure that PP woven bag printing meets industry standards while satisfying customer expectations.