Understanding Critical Woven Bag Parameters for Quality Control

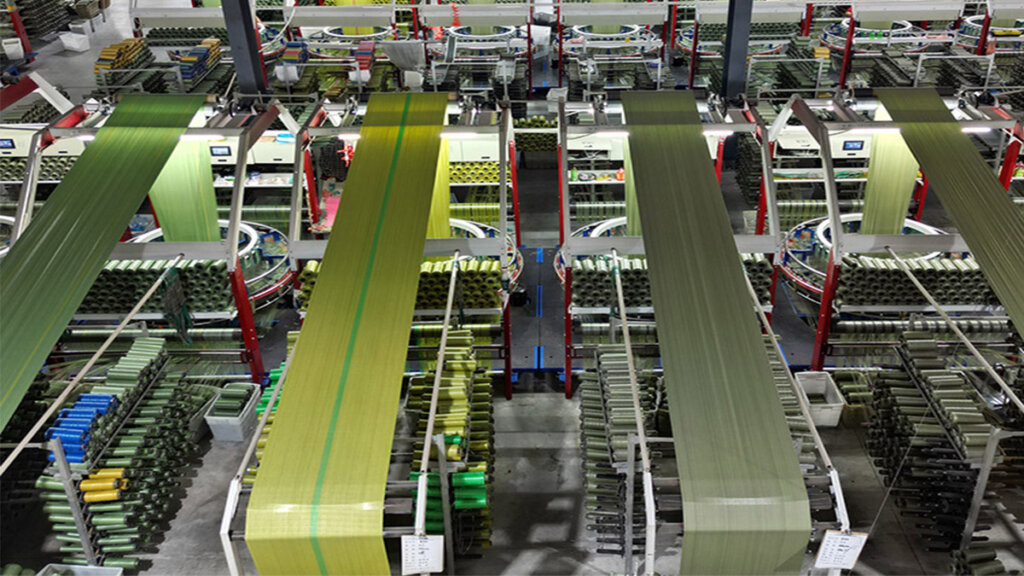

Woven polypropylene bags are essential packaging solutions for agriculture, construction, and industrial applications. To ensure optimal performance, manufacturers and buyers must understand these four crucial technical specifications that determine quality, durability, and cost-efficiency.

1. Weaving Density Tolerance

Definition:

Weaving density tolerance refers to the allowable variation in the number of flat yarns (tape strands) per unit length compared to the standard specification.

Key Points:

- Measured by extra/missing yarns per 10cm width

- Affects fabric strength and load-bearing capacity

- Tighter tolerances indicate higher quality control

- Typical industry tolerance: ±1-2 yarns/10cm

Impact:

Exceeding tolerance limits can cause:

✔ Reduced tensile strength

✔ Uneven surface texture

✔ Potential bag failure under stress

2. Gram Per Square Meter (GSM)

Definition:

GSM measures fabric weight in grams per square meter, determined by:

- Warp/weft yarn density

- Tape thickness (typically 0.04-0.12mm)

Technical Considerations:

| GSM Range | Common Applications |

|---|---|

| 60-80 GSM | Light-duty packaging |

| 80-100 GSM | Agricultural products |

| 100-120 GSM | Heavy-duty industrial use |

Why It Matters:

- Directly correlates with load capacity

- Higher GSM = Increased material cost (+15-20% per 10GSM)

- Critical for cost optimization in bulk production

3. Tensile Load (Warp & Weft Strength)

Testing Standards:

- ISO 13934-1 (Strip method)

- ASTM D5034 (Grab test)

Typical Performance Data:

| Direction | Strength Range* |

|---|---|

| Warp | 30-50 N/cm |

| Weft | 25-45 N/cm |

*For 90GSM woven PP fabric

Key Factors Affecting Strength:

- Polymer quality (virgin vs. recycled PP)

- Tape extrusion temperature

- Lamination (if applied)

4. Fabric Width & Shrinkage

Width Specifications:

- Tubular fabric: Expressed as folded width (½ circumference)

- Common widths: 45cm, 50cm, 55cm, 60cm

Shrinkage Considerations:

- Typical shrinkage: 2-5% after processing

- Caused by:

- Thermal contraction during cooling

- Tension release during conversion

Production Impact:

- Must be accounted for in bag design

- Affects final bag dimensions after:

- Printing

- Cutting

- Sewing/stitching

Quality Control Recommendations

- Raw Material Inspection

- Verify PP resin MFI (Melt Flow Index)

- Monitor tape thickness consistency

- In-Process Checks

- Hourly GSM sampling

- Tensile strength testing (every 2 rolls)

- Final Product Validation

- Measure actual shrinkage

- Confirm seam strength

Industry Trends & Data

- Premium markets (EU/US) demand:

- ≤±1 yarn/10cm density tolerance

- ≤3% width variation

- ISO-certified tensile testing

- Cost-saving tip:

Optimize GSM by: - Using narrower tapes (reduces material by 8-12%)

- Precision loom calibration

For high-performance woven bags, partner with manufacturers who:

✔ Document all technical parameters

✔ Provide third-party test reports

✔ Offer customized GSM/tolerance options

Contact us today for technical specifications sheets and samples of our ISO 9001-certified woven bags!